News

- Home

- News

- News Category

- What Is Wood Veneer? Types, Benefits, and Common Uses Explained

What Is Wood Veneer? Types, Benefits, and Common Uses Explained

Wood veneer is everywhere - from hotel lobbies to luxury homes, you're probably looking at it more than you realize. This thin slice of real wood makes beautiful, exotic species affordable for projects that could never use solid timber. Understanding veneer can change how you approach your next woodworking project.

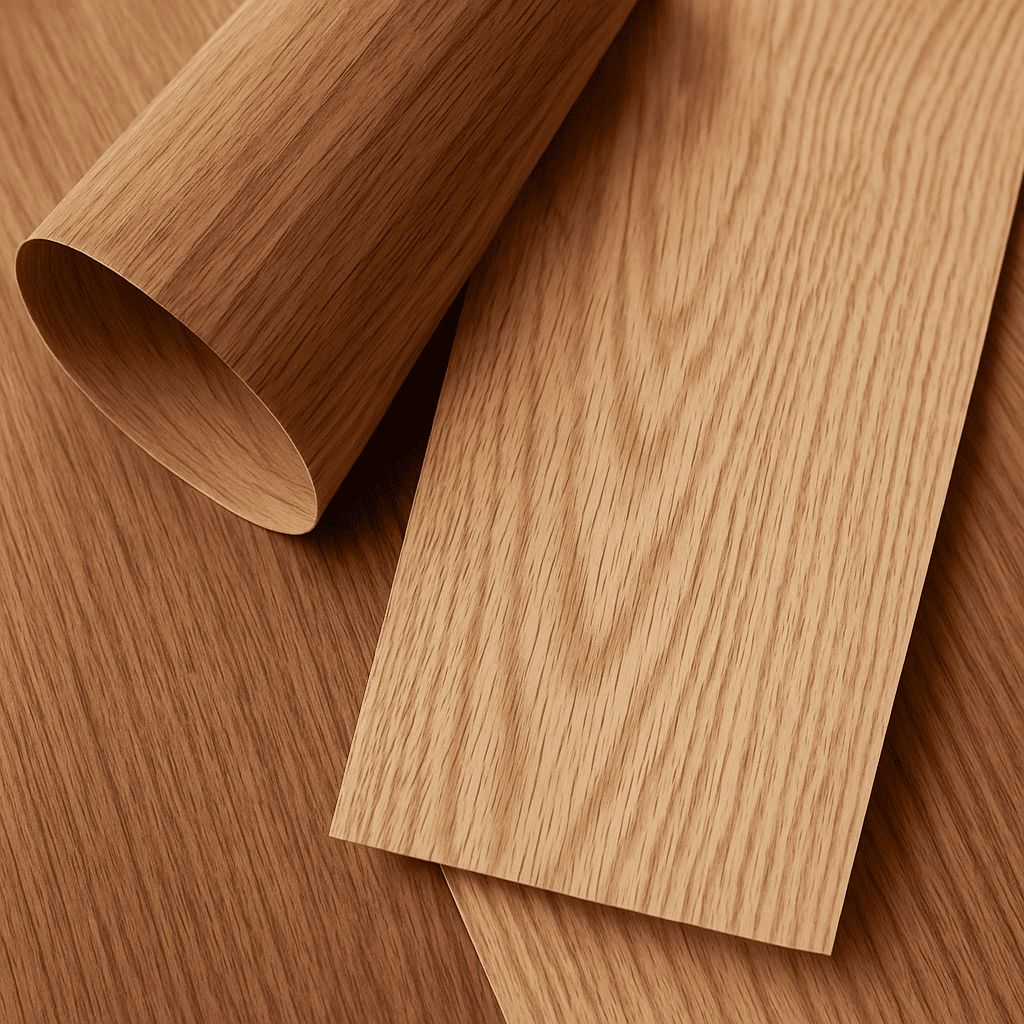

What Exactly is Wood Veneer?

Wood veneer is a thin sheet of real, natural wood, typically sliced to a thickness of 0.5mm to 3mm, that is used to overlay less expensive or engineered wood surfaces, such as cabinetry, furniture, and wall panels. This material is carefully cut from logs to preserve the natural wood grain and inherent beauty. Unlike synthetic materials or laminate, natural wood veneer maintains authentic characteristics, including unique grain patterns, color variations, and natural markings that reflect the tree's growth environment. The manufacturing process begins with selecting high-quality logs from sustainable sources worldwide. These logs are precisely sliced using specialized machinery to create thin sheets, a process that maximizes timber utilization while preserving the wood's inherent beauty.

At Ho Bridge, we source timber globally to produce over 100 variations of natural wood veneer. From popular species like Cherry, Oak, Walnut, Birch, and Maple to exotic specialties including Jatoba, Andiroba, Laurel Burl, and figured veneers, each piece reflects the authentic grain and color characteristics of its source tree, offering a premium and versatile wood veneer solution for any project.

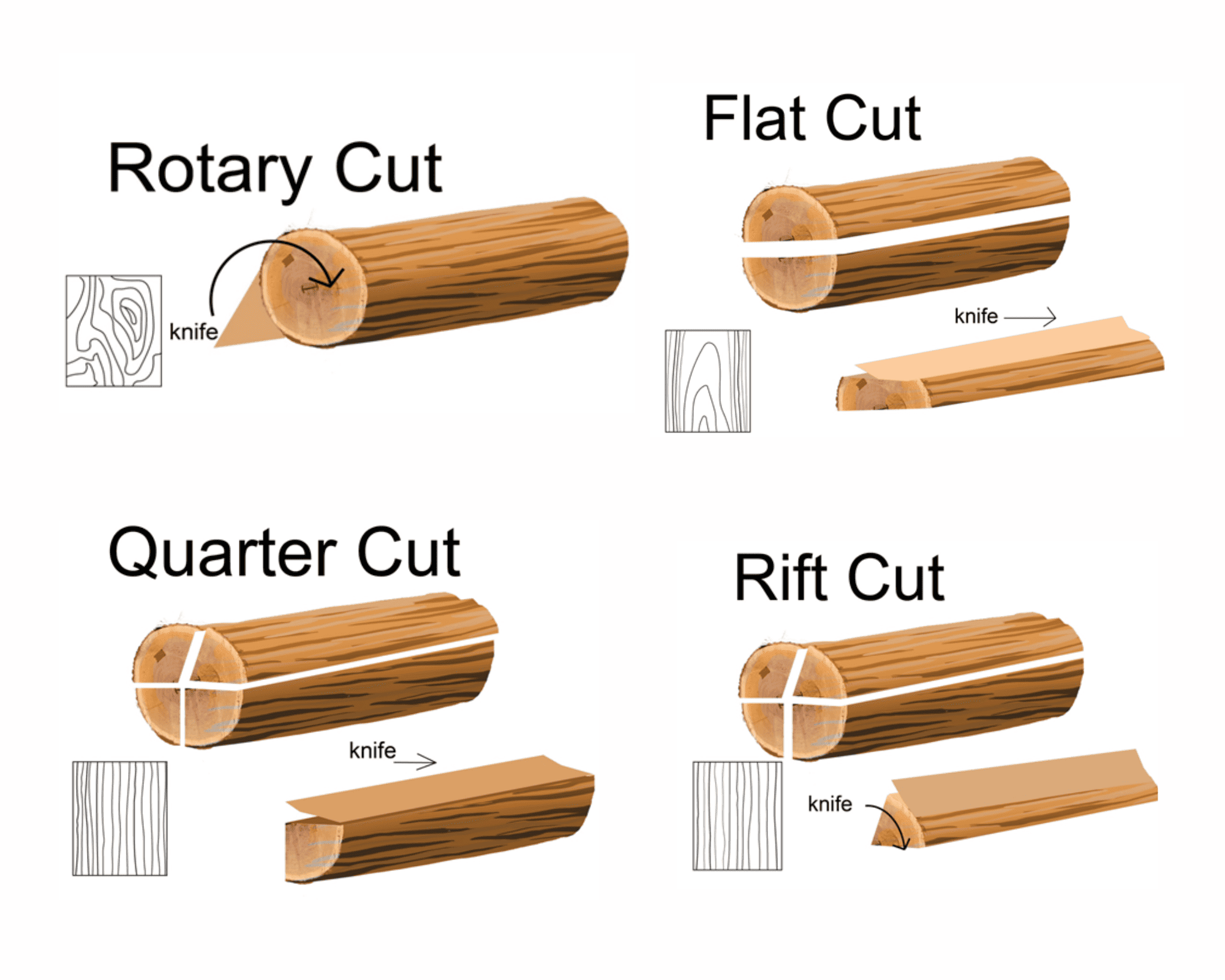

Understanding Wood Veneer Cuts: Key to Different Veneer Types and Grain Patterns

Before exploring the cuts, a common wood veneer type distinction is by its construction: Paper-Backed Veneer (for stability) and Reconstituted Veneer (an eco-friendly, engineered type that mimics exotic species).

Now, let's unveil the primary wood veneer cuts that define the sheet's final look:

- Rotary Cut Veneer:

This wood veneer cut is made by spinning the entire log on a lathe against a cutting blade, like unwrapping a scroll. It yields the widest sheets and is the most economical type of wood veneer. The result is a bold, sweeping grain pattern with a dramatic, cathedral-like appearance—perfect when you want an eye-catching visual impact. - Plain Sliced Veneer (Flat Cut):

The most traditional wood veneer cut, created by slicing the log lengthwise. This produces sheets with the classic, repeating "cathedral" grain figure. It's the go-to wood veneer type for cabinetry and wall paneling where you need a uniform, familiar appearance across large areas. - Quarter Sliced Veneer:

This precise veneer cut involves slicing the log at a 90-degree angle to the growth rings, resulting in straight, uniform, and parallel grain lines with minimal variation. This clean, linear wood veneer type is ideal for modern designs that emphasize sleek consistency and is known for producing "fleck" in some species like oak. - Rift Cut Veneer:

A specialized wood veneer cut often used for oak and similar species. It's designed to reduce the prominent ray and growth ring patterns, producing straight grain lines with subtle variation. This method creates an elegant, refined wood veneer type that provides a straight, linear look without the starkness of Quarter Slicing.

Why Choose Wood Veneer?

Wood veneer offers a unique combination of aesthetic appeal, environmental responsibility, and practical performance, making it a preferred material across a wide range of applications.

- Sustainability & Resource Maximization

- A single log that might yield only a few solid wood boards can produce veneer that covers hundreds of square feet.

- This efficient use of resources reduces waste significantly and makes high-end wood species more accessible.

- Ho Bridge offers FSC®-certified products upon request, ensuring the veneer meets the highest environmental standards.

- Cost-Effectiveness Without Compromise

- Veneer provides the authentic look and feel of premium or exotic wood species—such as figured walnut or burls—at a fraction of the cost of solid wood.

- Enables designers to use luxurious woods that would otherwise be cost-prohibitive, expanding creative potential within budget constraints.

- Superior Stability & Performance

- When applied to stable substrates, wood veneer is less prone to warping, splitting, or cracking than solid wood.

- Ideal for projects that require dimensional stability, especially in:

-Varying humidity environments

-Large or flat surface application

- Design Versatility & Creative Freedom

- Veneer allows for advanced techniques such as:

-Book-matching (for symmetrical grain patterns)

-Sequence-matching (for a continuous grain flow)

-Inlay work (for intricate design details) - Can be bent around curves and applied to a variety of surfaces, enabling designs that are often impossible with solid wood.

- Veneer allows for advanced techniques such as:

Where Wood Veneer Shines: Common Uses & Applications

Wood veneer is far more than a staple of traditional woodworking—its versatility makes it a valuable material across industries that demand both aesthetic excellence and functional performance.

- Furniture Manufacturing:

One of the largest markets for wood veneer is furniture production. Both residential and commercial furniture makers rely on veneer to deliver stunning tabletops, cabinet fronts, and decorative accents. Veneer allows the use of premium wood species without sacrificing structural integrity or exceeding budget constraints—perfect for high-end looks with reliable performance. - Architectural and Interior Design:

Wood veneer plays a key role in transforming interior spaces with the warmth and beauty of natural wood. It's commonly used for:- Wall paneling systems

- Ceiling installations

- Architectural millwork

- Cabinetry and Built-in Solutions:

Across kitchens, bathrooms, and custom storage spaces, veneer offers both visual appeal and practical benefits. It's widely used in:- Kitchen cabinets

- Bathroom vanities

- Entertainment units

- Built-in shelving and storage

- Specialty and Luxury Applications

Veneer also excels in niche, high-end markets where quality and performance are non-negotiable. Examples include:- Yacht interiors

- Automotive interiors

- Musical instruments

These applications showcase veneer's unique ability to combine beauty, durability, and technical performance.

Wood Veneer FAQs

- Q: Is veneer better than laminate?

A: Veneer is not better than laminate; it's a matter of preference. Veneer offers a natural wood look and feel, while laminate is more durable, scratch-resistant, and requires less maintenance. (Learn More About Wood Veneer vs Laminate.) - Q: Is veneer cheaper than hardwood?

A: Yes, veneer is significantly cheaper than hardwood. It provides the look of solid hardwood at a much lower cost. - Q: Is veneer wood water-poor?

A: Yes, veneer is not a good choice for wet areas. Veneer is susceptible to water damage, which can cause it to warp or peel. - Q: How long does a veneer last?

A: A veneer can last for 15-20 years or even longer with proper care. Its lifespan depends on the quality of the veneer and the substrate it's applied to, as well as the amount of wear and tear it receives.

Whether you're a furniture maker seeking consistency, an architect designing a signature space, or a craftsperson exploring new creative possibilities, wood veneer bridges the gap between natural beauty and engineered performance—delivering authentic wood aesthetics with modern functionality.

Explore more of Ho-Bridge's premium wood veneer collections and bring distinctive style and innovation to your designs.